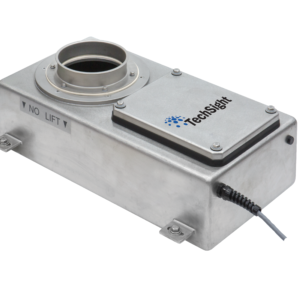

The ProCheck Liquid Line Metal Detector systems are designed for liquids, pastes, slurries or other viscous products where high-sensitivity metal detection is required. The system can be mounted vertically or horizontally. Available in pipe sizes 1.5”-4” diameter. When metal is detected in the product flow, a reject signal is channeled to one of the available output relays. The output relay can be used to activate a ball valve, control a visual or audio alarm, or send a signal to a PLC.

Features:

1. Versatile Application:

ProCheck’s Liquid Line Metal Detector is tailored for high-sensitivity metal detection in liquids, pastes, slurries, and viscous products.

2. Flexible Installation:

This system can be effortlessly mounted in either vertical or horizontal orientations to seamlessly fit your production line.

3. Wide Diameter Range:

Available for pipe sizes ranging from 1.5″ to 4″ in diameter, ensuring compatibility with various liquid processing setups.

4. Precise Detection:

Upon detecting metal in the product flow, the system triggers a reject signal to output relays, enabling actions such as activating a ball valve, initiating alarms, or signaling a PLC.

5. Enhanced Product Safety:

ProCheck’s Liquid Line Metal Detector contributes to product safety by swiftly identifying and addressing metal contaminants in your liquid processing, bolstering quality assurance.